Thermal Shock Testing Service

Ensure the Reliability of Your Products

BE Analytic is a NABL accredited laboratory. BE Analytic has established world class test facility for quality and reliability assurance of different Mechanical, Electronic and Electromechanical Products.

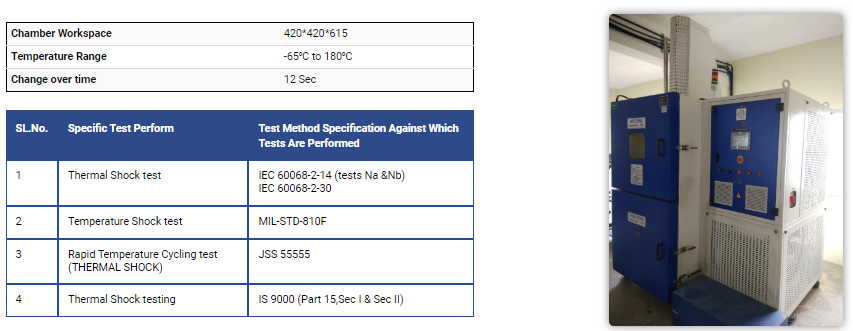

We offer comprehensive Thermal Shock/ Temperature Shock testing services to ensure the reliability and performance of your products. Our state-of-the-art testing facilities and experienced team of engineers enable us to provide customized testing solutions that meet your specific needs.

We conduct various types of Thermal Shock tests as per different national and international test standards like, IEC 60068-2-14, IEC 60068-2-30, MIL-STD-810F, JSS 55555, IS 9000 (Part 15, Sec I & Sec II) and so on.

What is Thermal Shock Test?

Thermal shock or temperature shock testing is a type of environmental test that subjects a product to sudden and extreme changes in temperature to assess its ability to withstand rapid temperature changes. The test involves rapidly transferring a product from one temperature extreme to another, typically from hot to cold or cold to hot, and measuring its response to the change in temperature. The test is designed to simulate the stresses that a product may experience during its lifetime due to thermal expansion and contraction, which can cause mechanical stress and result in failure. The results of the test can be used to identify potential weaknesses in the product’s design or materials and make improvements to increase its reliability and durability.

BE Analytics Thermal Shock Test Facilities

-

Thermal Shock test

-

Temperature Shock test

-

Rapid Temperature Cycling test (THERMAL SHOCK)

-

Thermal Shock testing

What is Temperature Shock Test?

A Temperature shock test is a type of environmental test that exposes a product to rapid and extreme temperature changes to evaluate its ability to withstand thermal stress. The test involves quickly transferring the product from a high-temperature environment to a low-temperature environment or vice versa, resulting in thermal shock. The purpose of the test is to determine whether the product can handle sudden temperature changes without suffering from damage or failure. Temperature shock testing is commonly used in the automotive, aerospace, and electronics industries, among others, to assess product reliability and quality.

What is Thermal Shock Testing?

Thermal shock testing is a type of environmental testing that subjects a test sample to sudden and extreme temperature changes to determine its ability to withstand rapid changes in temperature without failure. During the test, the sample is subjected to a high temperature, and then quickly exposed to a low temperature, or vice versa. This rapid change in temperature can cause thermal stress and induce failures in the sample if it is not designed to handle such changes. The test is commonly used in industries such as aerospace, electronics, automotive, and military to ensure that products can withstand the thermal stresses of their intended environments.

What is Rapid Temperature Cycling Test?

Rapid Temperature Cycling (RTC) test is a type of thermal cycling test where the temperature is quickly cycled between high and low extremes in a short amount of time. This test is often used to evaluate the reliability and durability of products that are subject to rapid temperature changes, such as electronic components, automotive parts, and aerospace equipment. The RTC test is particularly useful for identifying potential failures due to thermal stress, such as cracking or delamination of materials, changes in dimensional stability, or changes in electrical properties. By subjecting products to RTC testing, manufacturers can ensure that their products can withstand the rapid temperature changes they may experience in real-world use.

Why Choose us?

-

State-of-the-art facilities and equipment

-

Experienced and knowledgeable engineers

-

Quick turnaround times

-

Competitive pricing

-

Customized testing solutions to fit your specific needs

Reach us here...

Get started with your next project. Contact us now.