Reach us here...

Get started with your next project. Contact us now.

Ensure the Reliability of Your Products

EMI and EMC testing are crucial steps in ensuring that electronic devices meet regulatory requirements for electromagnetic compatibility. EMI (electromagnetic interference) refers to any disturbance in the electromagnetic field that affects the performance of an electronic device. EMC (electromagnetic compatibility) refers to the ability of an electronic device to operate without interference in its intended electromagnetic environment.

In today’s world, where electronic devices are becoming more complex and interconnected, EMI EMC testing has become even more important. Failure to meet regulatory requirements can result in costly delays and product recalls, damage to brand reputation and even safety hazards.

EMI testing stands for Electromagnetic Interference Testing which is a type of testing that is used to evaluate the ability of electronic devices and systems to operate without causing or being affected by unwanted electromagnetic interference (EMI). EMI can occur when electromagnetic energy from one device interferes with the operation of another device, leading to various issues such as distorted signals, data loss and malfunction.

EMI testing is typically performed to ensure that electronic devices and systems comply with regulatory requirements, such as FCC, CE, CISPR and IEC standards.

This type of testing evaluates the amount of electromagnetic energy that is radiated by a device or system into the surrounding environment. The test measures the field strength of the radiated energy at different frequencies and distances from the device.

This type of testing evaluates the amount of electromagnetic energy that is conducted through power and signal cables connected to a device or system. The test measures the amount of unwanted noise that is conducted along the cables.

This type of testing evaluates the ability of a device or system to withstand sudden changes in voltage or current that can cause electromagnetic interference. The test measures the susceptibility of the device or system to transient events such as lightning strikes or power surges.

Magnetic EMI testing assesses electromagnetic interference by measuring magnetic fields emitted from electronic devices. It identifies potential sources of interference affecting electronic performance and compliance with regulatory standards.

Overall, EMI testing is an essential process that ensures electronic devices and systems can operate effectively in the presence of electromagnetic interference.

EMC testing stands for Electromagnetic Compatibility Testing. It is a type of testing that evaluates the ability of electronic devices and equipment to operate properly in their intended electromagnetic environment and not interfere with other nearby devices or equipment.

EMC testing can be divided into two main categories: emissions testing and immunity testing.

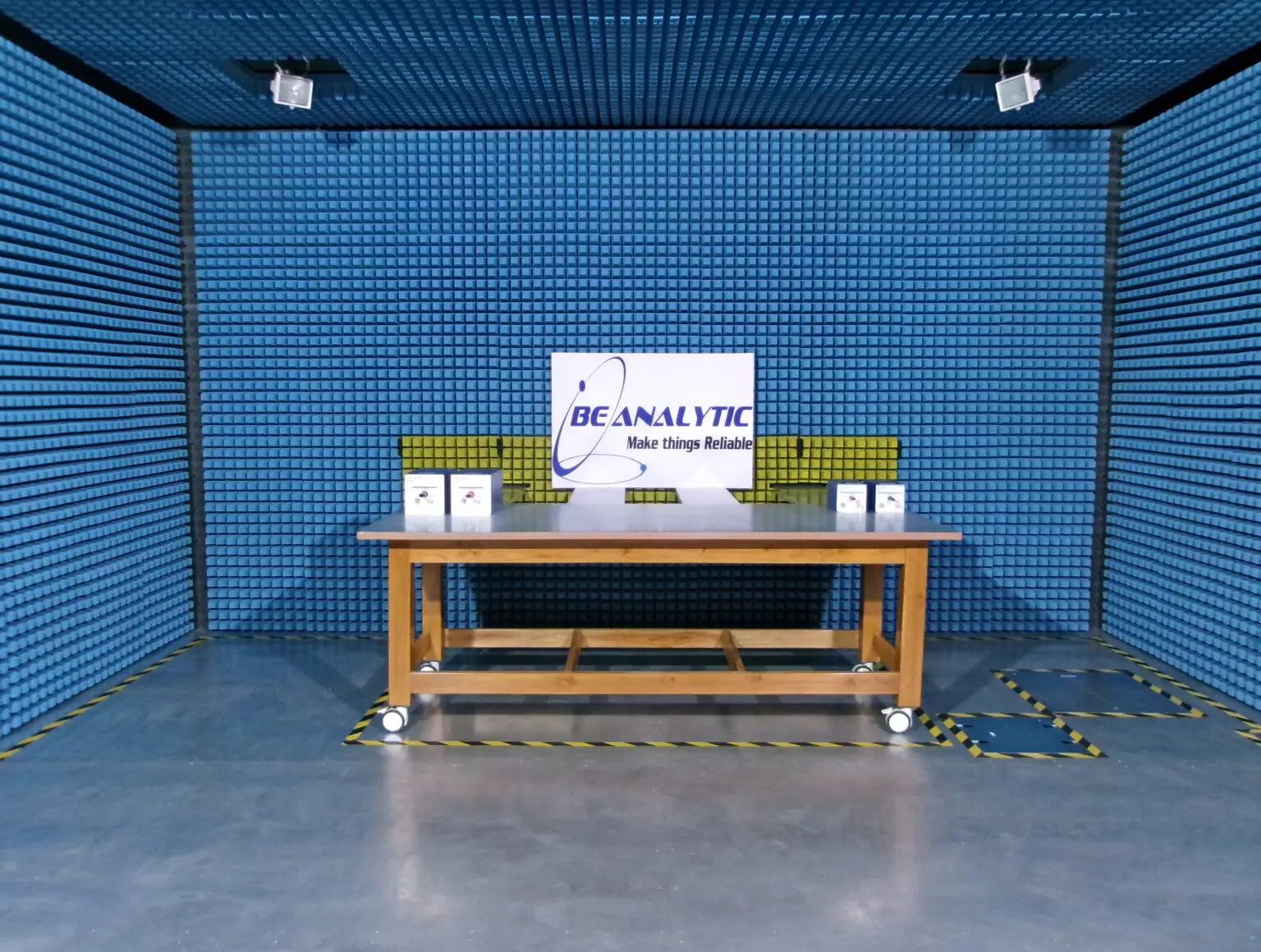

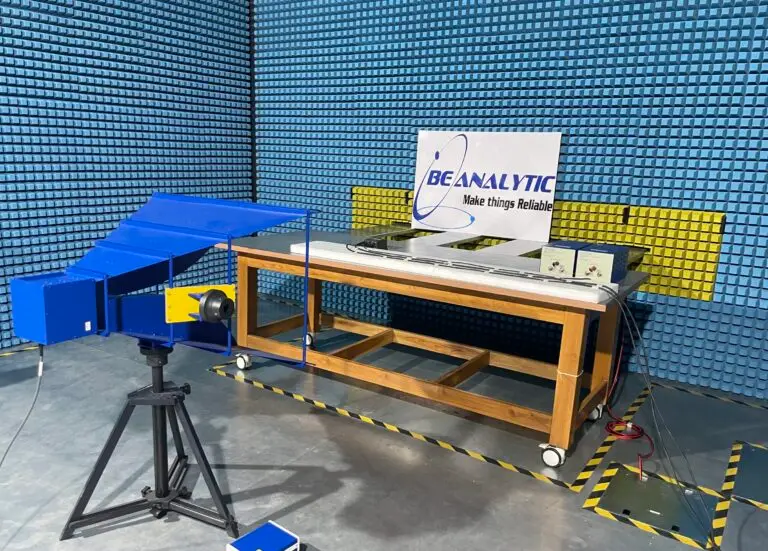

This type of testing measures the amount of electromagnetic energy that is emitted from a device and ensures that it does not exceed the legal limits. Emissions testing is done in a shielded room or anechoic chamber and measures the radiated and conducted emissions from the device.

This type of testing evaluates how well a device can function in the presence of electromagnetic interference (EMI) from other sources. Immunity testing is also done in a shielded room or anechoic chamber and involves subjecting the device to various electromagnetic fields to see if it continues to function properly.

There are various types of EMC testing that fall under emissions and immunity testing. Some of the most common types include:

Radiated Emissions Testing: This tests the amount of electromagnetic energy that is emitted by the device and radiated through the air.

Conducted Emissions Testing: This tests the amount of electromagnetic energy that is emitted by the device and conducted through its power and signal cables.

Radiated Immunity Testing: This tests how well the device can function in the presence of electromagnetic energy that is radiated through the air.

Conducted Immunity Testing: This tests how well the device can function in the presence of electromagnetic energy that is conducted through its power and signal cables.

Electrostatic Discharge (ESD) Testing: This tests the device’s ability to withstand electrostatic discharge, which can damage electronic components.

Transient Immunity Testing: This tests the device’s ability to function in the presence of transient voltages or currents, which can occur during power surges or lightning strikes.

Overall, EMC testing is crucial for ensuring that electronic devices and equipment can function properly and coexist with other devices in their electromagnetic environment.

It is a radiated test that measures the level of Electromagnetic Interference (EMI) a device generates and radiates while it is operational at its normal and it confirms whether the emissions level is within the specified limits.

It is a conducted test that measures the level of Electromagnetic noise the device is generating and while it is operational at its normal the same noise might travel along the cable or I/O lines and cause interference to the other systems.

It is a radiated test that validates the EUT, how well the EUT performs when exposed to the level of radiated electromagnetic noise it will encounter in its expected operating environment.

It is a conducted test that validates the EUT, how well the EUT performs or reacts to the electromagnetic noise generated from another source device and while the same noise may enter the EUT through the cable or I/O lines.

| S.No | Test Name | Standard | Test ID |

| 1 | Conducted Emissions, Power Leads, 30 Hz to 10 KHz (P41) | MIL461- E/F/G | CE101 |

| 2 | Conducted Emissions, Power Leads, 10 KHz to 10 MHz (P49) | MIL461- E/F/G | CE102 |

| 3 | Conducted Susceptibility, Power Leads, 30 Hz to 150 KHz (P61) | MIL461- E/F/G | CS101 |

| 4 | Conducted Susceptibility, Bulk Cable Injection, 10 KHz to 200 MHz (P77) | MIL461- E/F/G | CS114 |

| 5 | Conducted Susceptibility, Bulk Cable Injection, Impulse Excitation (P86) | MIL461- E/F/G | CS115 |

| 6 | Conducted Susceptibility, Damped Sinusoidal Transients, Cables & Power Leads, 10 KHz to 100 MHz (P91) | MIL461- E/F/G | CS116 |

| 7 | Conducted Susceptance ESD (P111) | MIL461- E/F/G | CS118 |

| 8 | Radiated Emissions, Magnetic Field, 30 Hz to 100 KHz (P118) | MIL461- E/F/G | RE101 |

| 9 | Radiated Emissions, Electric Field, 10 KHz to 18 GHz (P124) | MIL461- E/F/G | RE102 |

| 10 | Radiated Susceptibility, Electric Field, 2 MHz to 40 GHz (P136) | MIL461- E/F/G | RS103 |

| 11 | Radiated Susceptibility, Magnetic Field 30 Hz to 100 kHz (P142) | MIL461- E/F/G | RS101 |

S.No | Test Name | Standard | Test ID |

1 | Voltage Transient Emission Test | AUTO | ISO 7637-2 |

2 | Transient Immunity Test | AUTO | ISO 7637-2 |

3 | Electrical disturbances from Electrostatic Discharge (Powered-up test) | AUTO | ISO 10605-2008 |

4 | Electrical disturbances from Electrostatic Discharge (Unpowered test) | AUTO | ISO 10605-2008 |

5 | Direct radio frequency (RF) power injection | AUTO | ISO 11452-2 (2) |

6 | Bulk Current Injection (BCI) | AUTO | ISO 11452-4 (2) |

7 | Conducted Emission, 100 kHz to 108 MHz [5 µH / 50 ohm] | AUTO | CISPR25 |

8 | Radiated Emission, 9 kHz – 6 GHz at 1 Meter | AUTO | CISPR25 |

9 | Test methods for electrical disturbances | AUTO | ISO_16750-2_2010 (E) |

S.No | Product/material | Specific Tests performed | Test Standard |

1 | Commercial | Conducted Emission | CISPR 11 |

2 | Industrial | Radiated Emission | CISPR 15 |

3 | Scientific | RF Radiated Susceptibility | CISPR 32 |

4 | Medical | Electrostatic Discharge immunity | IEC 61000-4-2 |

5 | Information technology | Electrical Fast transient (EFT)/Burst immunity | IEC 61000-4-3, IEC 61000-4-4 |

6 | Multimedia | Conducted RF Susceptibility | IEC 61000-4-5 |

7 | Lighting Equipment | Power frequency | IEC 61000-4-6 |

Magnetic field immunity | IEC 61000-4-8 | ||

Voltage Dips, Short Interruption | IEC 61000-4-11 | ||

Voltage Variations immunity |

S.No | Test Name | Standard |

1 | Magnetic Effects | DO160 |

2 | Power Input | DO160 |

3 | Voltage Spikes | DO160 |

4 | Audio Frequency Conducted Susceptibility – Power Inputs | DO160 |

5 | Induced Signal Susceptibility | DO160 |

6 | Radio Frequency Susceptibility (Radiated and Conducted) | DO160 |

7 | Emission of Radio Frequency Energy | DO160 |

8 | Lightning Induced Transient Susceptibility | DO160 |

9 | Lightning Direct Effects | DO160 |

10 | Electrostatic Discharge | DO160 |

Subject | Organization | Standard |

Electro-Magnetic compatibility | EEC | 89/336/EEC |

Electro-Magnetic compatibility | CENELEC | EN 50081-2, EN 50121-1, EN 50121-2, EN 50121-3, EN 50121-4, IEC 61000-1, IEC 61000-2, IEC 61000-3, IEC 61000-4, IEC 61000-5. |

Conducted immunity level | CENELEC | EN 50082-2 |

Electrostatic discharge (ESD) | IEC | IEC 61000-4-2 |

Fast transient burst | IEC | IEC 61000-4-4 |

Get started with your next project. Contact us now.