Reach us here...

Get started with your next project. Contact us now.

Ensure the Reliability of Your Products

BE Analytic is a NABL accredited laboratory. BE Analytic has established a world-class test facility for quality and reliability assurance of different Mechanical, Electronic and Electromechanical Products. We offer comprehensive Solid and Water Ingress Protection Testing Services to ensure the reliability and performance of your products. Our state-of-the-art testing facilities and experienced team of engineers enable us to provide customized testing solutions that meet your specific needs.

We conduct various types of Solid and water Ingress Protection (IP) tests as per different national and international test standards like IEC 60529, ISO 20653 and so on.

Ingress Protection (IP) testing is a type of environmental testing that is used to determine the level of protection provided by an enclosure or casing against the intrusion of solid objects, dust, and water. The IP rating system was developed by the International Electrotechnical Commission (IEC) and is recognized internationally.

Solid Ingress Protection (IP) testing is conducted to evaluate the level of protection against solid objects such as dust, sand, dirt, and other particles. The test typically involves blowing dust or sand particles onto the product under test and checking for any ingress of the particles into the enclosure.

IP1X- Solid Foreign Object50mm Diameter Sphere: This rating means that the device is protected against solid foreign objects larger than 50mm in diameter.

IP2X- Solid Foreign Object12mm Diameter Test Finger: This rating means that the device is protected against solid foreign objects larger than 12mm in diameter, such as fingers or other objects.

IP3X- Solid Foreign Object2.5mm Steel Wire: This rating means that the device is protected against solid foreign objects larger than 2.5mm in diameter, such as thin wires or small tools.

IP4X- Solid Foreign Object1mm Steel Wire: This rating means that the device is protected against solid foreign objects larger than 1mm in diameter, such as small wires or screws.

IP5X- Limited Ingress Protection: This rating means that the device is protected against dust to a limited extent, but some dust may still enter the device.

IP6X- Dust Tight Protection: This rating means that the device is completely protected against dust and no dust can enter the device.

IP5K- Dust Protected: This rating means that the device is protected against dust that may be encountered during normal use.

IP6K- Dust Tight: This rating means that the device is completely protected against dust and no dust can enter the device, even in the harshest environments.

Ingress Protection (IP) testing is a type of environmental testing that is used to determine the level of protection provided by an enclosure or casing against the intrusion of solid objects, dust, and water. The IP rating system was developed by the International Electrotechnical Commission (IEC) and is recognized internationally.

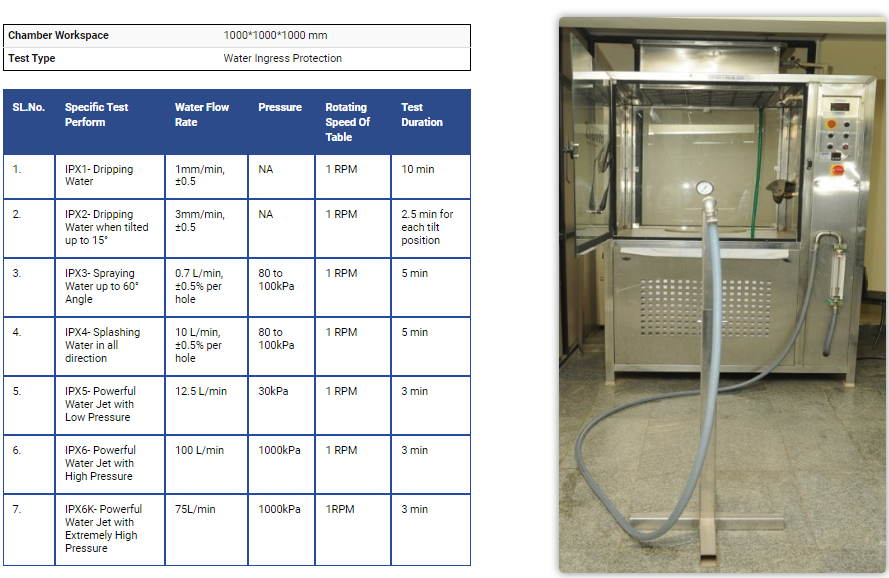

Water Ingress Protection (IP) testing is conducted to evaluate the level of protection against water. The test typically involves spraying water onto the product under test at varying pressures and for varying durations and checking for any ingress of water into the enclosure.

IPX1 – Dripping Water (Rain Test): The device or product is exposed to vertically falling water drops, with a flow rate of 1mm/min for 10 minutes. The test is conducted to verify the protection against dripping water.

IPX2 – Dripping Water when tilted up to 15°: The device or product is exposed to vertically falling water drops, with a flow rate of 3mm/min for 10 minutes, while the device is tilted at an angle of 15 degrees. The test is conducted to verify the protection against dripping water when the device is slightly tilted.

IPX3 – Spraying Water up to 60° Angle: The device or product is exposed to spraying water from a nozzle, with a flow rate of 7.5 liters/min for 5 minutes. The water is sprayed at an angle of up to 60 degrees from the vertical axis. The test is conducted to verify the protection against water sprays from various angles.

IPX4 – Splashing Water in all directions: The device or product is exposed to splashing water from all directions, with a flow rate of 10 liters/min for 5 minutes. The test is conducted to verify the protection against splashing water from all directions.

IPX4K – Water spray test: This is a specialized test that simulates water spray from a high-pressure cleaning device. The device or product is exposed to high-pressure water spray with a flow rate of 10 liters/min, with a pressure of 80-100 bar, and the water temperature is around 80°C. The test is conducted for verifying the protection against water spray from high-pressure cleaning devices.

IPX5 – Powerful Water Jet with Low Pressure: The device or product is exposed to powerful water jets with a flow rate of 12.5 liters/min, with a pressure of 30 kN/m² for at least 3 minutes. The test is conducted to verify the protection against powerful water jets from a low-pressure device.

IPX6 – Powerful Water Jet with High Pressure: The device or product is exposed to powerful water jets with a flow rate of 100 liters/min, with a pressure of 100 kN/m² for at least 3 minutes. The test is conducted to verify the protection against powerful water jets from a high-pressure device.

IPX6K: This test involves a powerful water jet with extremely high pressure, which is used to test the water resistance of a product. The test is designed to simulate the conditions of high-pressure washing, such as might be encountered in industrial or agricultural settings.

IPX7: This test involves immersing the product in water for a duration of 30 minutes, to test its ability to resist water ingress. The test is designed to simulate conditions such as accidental submersion in shallow water, or exposure to heavy rain or splashing.

IPX6K: This test involves a powerful water jet with extremely high pressure, which is used to test the water resistance of a product. The test is designed to simulate the conditions of high-pressure washing, such as might be encountered in industrial or agricultural settings.

IPX9K: This test involves powerful high-temperature water jets, which are used to test the water resistance of a product under extreme conditions. The test is designed to simulate conditions such as exposure to high-pressure steam cleaning or other harsh environments where water ingress is a concern.

High Pressure Wash: This test involves high-pressure wash jets, which are used to test the water resistance of a product under extreme conditions. The test is designed to simulate conditions such as exposure to high-pressure washing or other harsh environments where water ingress is a concern.

Get started with your next project. Contact us now.