FRACAS – Failure Reporting and Corrective Action System

What is FRACAS?

Leverage failure data to drive actionable insights that improve reliability, lower operational costs, improve product quality, and ensure ongoing Railway RAMS compliance during operations and maintenance.”

“From failures to foresight—enhancing reliability, reducing O&M costs, and ensuring Railway RAMS compliance.”

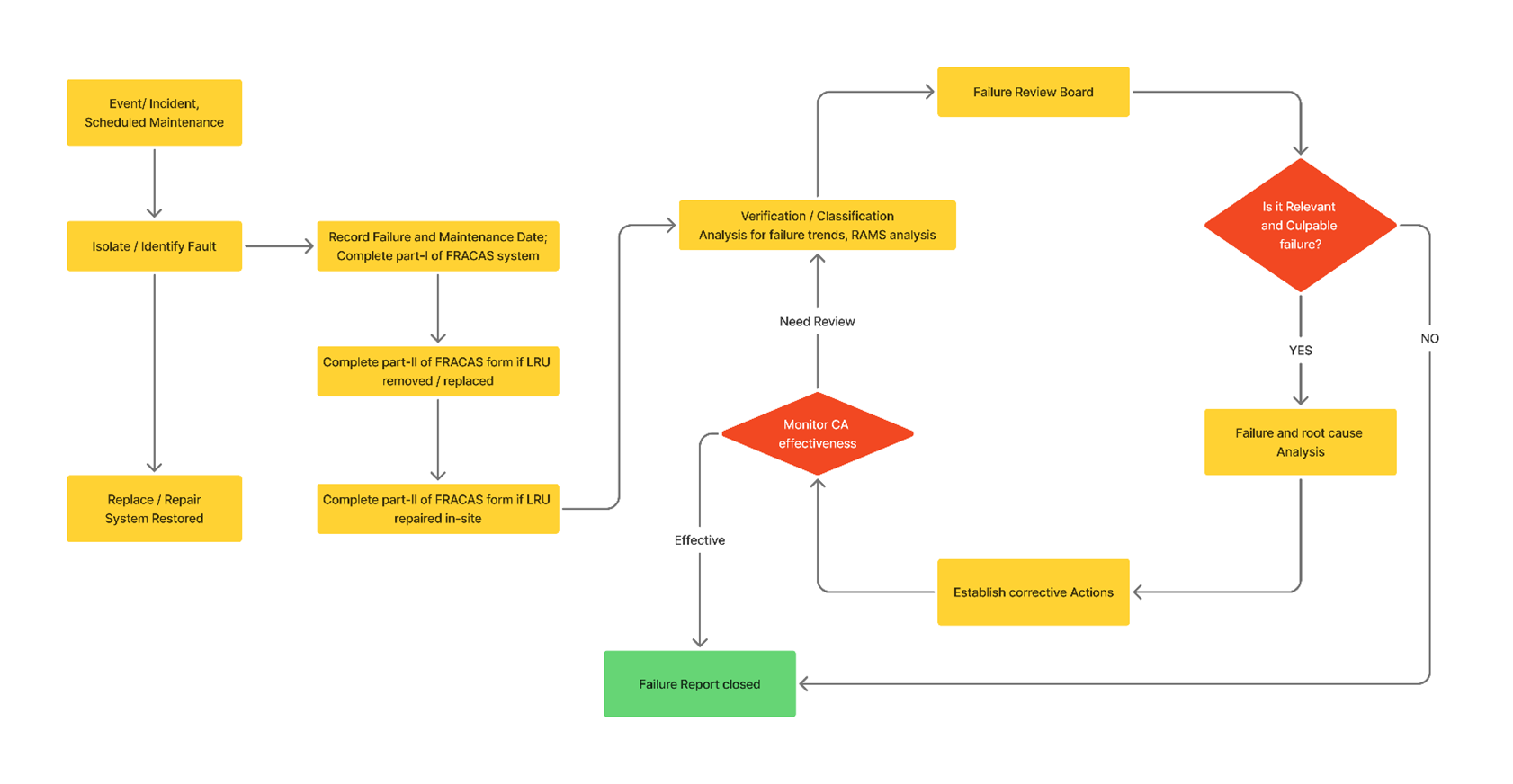

FRACAS (Failure Reporting, Analysis, and Corrective Action System) is a structured and systematic approach to identifying, analyzing, and resolving failures in products and processes. It creates a closed-loop process where failures are captured, investigated, corrected, and verified to prevent recurrence.

Our FRACAS tool directly fits to the requirements of O& M phase of EN 50126, fulfills all contractual requirements and completely customizable BoM, Dashboards, reports.

Why FRACAS Matters?

- Improves product reliability and system performance

- Reduces warranty and maintenance costs

- Enhances product quality and customer satisfaction

- Enables data-driven decision making

- Supports continuous improvement and compliance

Our FRACAS Solution

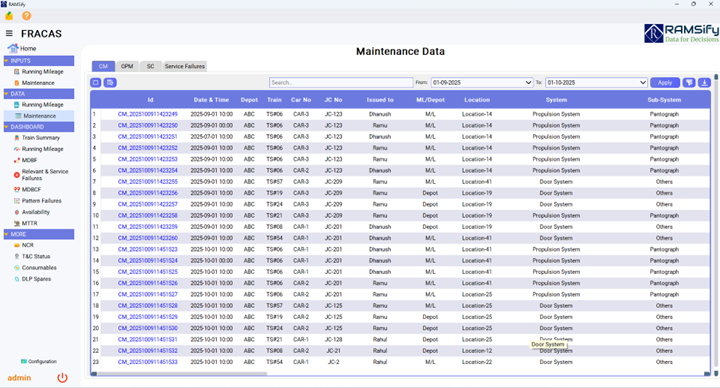

Beanalytic FRACAS is a powerful, web-based, and customizable platform designed to help organizations manage failures efficiently.

Key Features of Beanalytics FRACAS Software

- Easy failure reporting with structured workflows

- Centralized database for all failure and incident records

- Root cause analysis tools

- Corrective and preventive action tracking

- Automated alerts and notifications

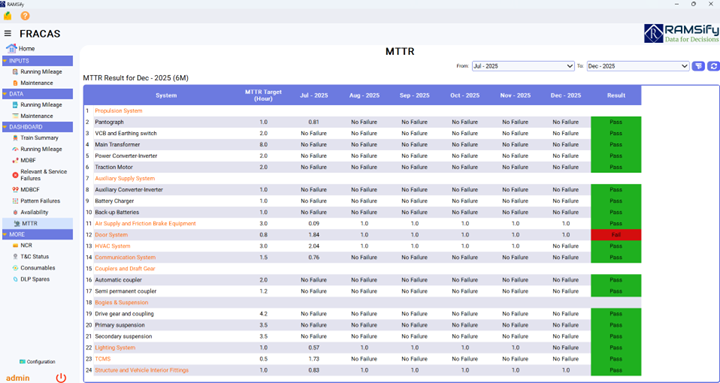

- Reliability metrics: MTBF, MTTR, Failure Rate, Weibull Analysis, Pareto distributions

- Warranty claim management

- Multi-location and multi-user support

- Advanced reporting in Excel, PDF, Word, and HTML formats

- Interactive dashboards and graphical analysis

- Effective Spare part managements and Life Cycle Cost

- Improvising Maintenance practices to help reduce the MTTR

Who Can Benefit?

- Reliability Engineers

- Quality Managers

- Maintenance Teams

- Operations Managers

- Product Development Teams

Industries Served

- Main Railway & Metro

- Automotive

- Aerospace & Defense

- Power & Energy

- Industrial Manufacturing

- Medical Devices

- Electronics & Semiconductors

Why Choose Beanalytic FRACAS:

Our FRACAS solution transforms raw failure data into valuable reliability intelligence. It not only helps you understand what went wrong but also ensures corrective actions are implemented and verified. This leads to measurable improvements in product performance and operational efficiency.

The FRACAS Lifecycle: A Closed-Loop System for Reliability Growth

Inside the Platform: A Closer Look at Our FRACAS Solution